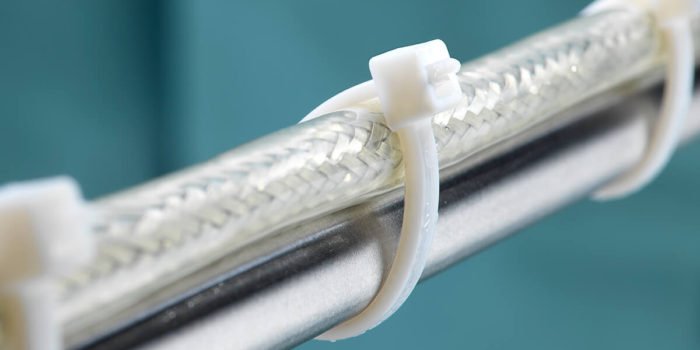

Strong-Ty™ Cable Ties: long-term UV resistance with Kynar® PVDF Nile Polymers, a leading manufacturer of high-performance cable ties, has expanded the range of industries they serve. Traditionally, cable ties made from Kynar® PVDF have shown durability across the solar and wire management industries. Known for their exceptional UV performance, smoke and flame resistance, and strong

Category Archives: Strong-Ty™ PVDF Cable Ties

REVIEW OF THE NILE POLYMERS EXHIBIT AT THE 2017 CHEM SHOW IN NEW YORK WE OFFER CORROSION-RESISTANT PRODUCTS MADE FROM KYNAR® PVDF FOR THE CHEMICAL PROCESS INDUSTRY PURISAN™ PVDF MIXERS Kynar® injection-molded impellers and Kynar® powder coated shafts. Impellers are available up to 6 inch diameter and shafts up to 1.25 inch diameter and 7

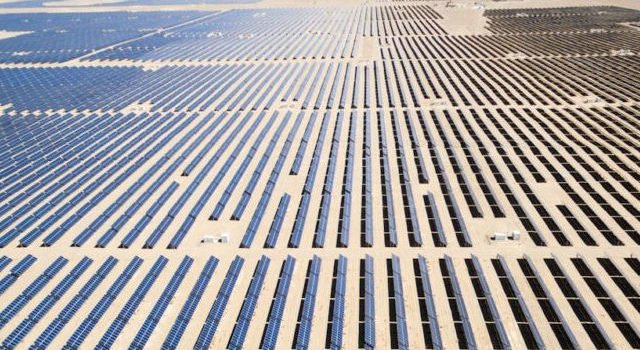

Strong-Ty™ Solar Cable Ties: unchanged after long-term UV exposure Wire and cable management on the photovoltaic backplane is critical for safety and electrical continuity. Why jeopardize an entire PV installation with cable ties made from substandard polymers such as nylon and polyethylene? Even behind photovoltaic panels, nylon and polyethylene cable ties fail in reflected UV

Strong-Ty™ PVDF Cable Ties: long-term UV resistance made possible by Kynar® Photovoltaic (PV) arrays have a 25-year plus life expectancy. However, the nylon and polyethylene cable ties can fail in a matter of months due to combinations of UV, temperature extremes, zinc chloride corrosion and high humidity. Commodity cable ties provide no dependable long-term solution

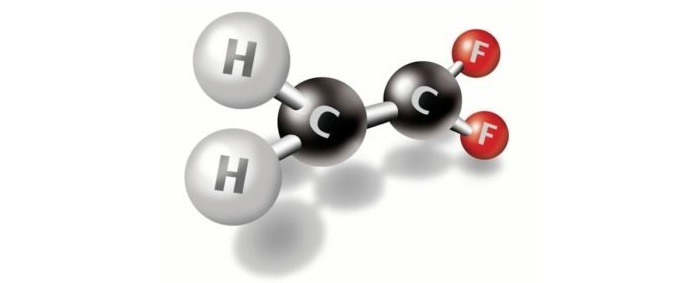

Strong-Ty™ Cable Ties: sterile cable ties made with Kynar® PVDF Strong-Ty™ PVDF cable ties can be sterilized by gamma radiation without any negative effects to material properties. The result is a cable tie ready for high purity applications in single-use pharmaceutical manufacturing or medical device equipment. To determine the effects of gamma radiation, a series of

Strong-Ty™ Cable Ties: superior performance with Kynar® PVDF The most common plastics used to manufacture cable ties are polyethylene, polypropylene, and nylon. These commodity plastics can come from thousands of sources including original manufacturers, compounders, and recyclers. Often the point of origin is price dependent and can change with each production run. While these cable

Strong-Ty™ Cable Ties: PVDF meets international regulations Concerns about material safety and traceability are more important than ever as cable ties made from inferior materials flood the market. In mission-critical applications polymer substitution or manufacturing shortcuts are unacceptable. How confident are you in your current cable tie? What materials, including additives, stabilizers, fillers, plasticizers and

Strong-Ty™: chemical resistant cable ties We choose to make our Strong-Ty™ cable ties from Kynar® PVDF and have never looked back. Kynar® PVDF offers a wider range of chemical resistance compared to other polymers. When your application involves aggressive chemical exposure at elevated temperatures, you need Strong-Ty™ chemical resistant cable ties. The following chart from