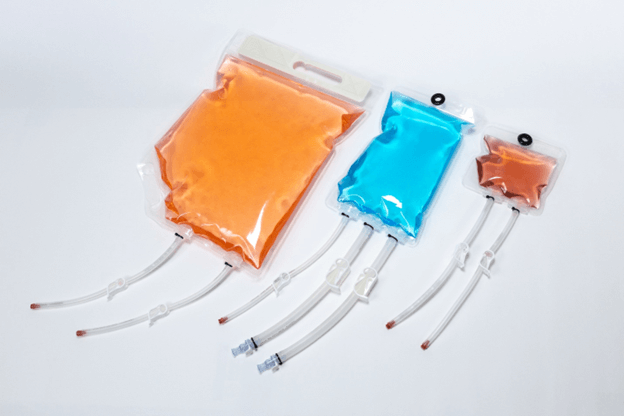

Made from Kynar® PVDF, StrongTy® cable ties are ideal for use with 2D and 3D bioprocessing bags. Resistant to aggressive environmental conditions, these cable ties are suitable for gamma, steam and chemical sterilization without compromising the mechanical strength of the fastener.

Using 100% new material, StrongTy® cable ties are injection molded and double-bagged in a cleanroom environment following ISO 13485 procedures. Kynar® PVDF is the cleanest polymer manufactured in the world today with contamination and impurities measured at the PPT level. From the base PVDF resin to the final injection molded product.

Strong-Ty® cable ties are 100% manufactured in the United States and fully lot traceable. No mystery, no contamination, no regrind and no worries. But we don’t just talk about how great Strong-Ty® cable ties are, we back up our claims with rigorous testing. Strong-Ty® cable ties meet the following recognized standards:

- USP Class VI

- ISO 10993-5

- REACH Compliance

- FDA CFR 21 177.2510

Additionally, Strong-Ty® cable ties are free from substances derived from animals or associated with BSE/TSE infectivity

We make the best cable ties made in the entire world. Using a tie made from junk commodity plastic makes the fastener the weakest link in your system. It’s a risk. Go with StrongTy® cable ties and eliminate your fastener problems.

Nile Polymers can provide evaluation samples along with test reports and our CofC. We are excited to serve your manufacturing needs.

Thank you for considering our cable ties.

You can find additional product details on our website

| Strong-Ty® Kynar® PVDF Cable Tie Properties | ||||||

| Part Number | Color | Length (in.) | Thickness (in.) | Width (in.) | Max Bundle Dia. (in.) | Tensile Strength (lbs.) |

| NPC204SN | Natural | 4 | 0.04 | 0.12 | 1.0 | 18 |

| NPC204N | Natural | 4 | 0.06 | 0.18 | 1.0 | 48 |

| NPC208N | Natural | 8 | 0.06 | 0.18 | 2.0 | 48 |

Nile Polymers

- (801) 203-3756

- sales@polymers.com