Light Link™ SLA PVDF Resin

Overview: Light Link™ liquid resin uses Kynar® PVDF to create UV crosslinked parts with a stereolithography (SLA) 3D printer. Our Light Link™ product is a novel photopolymer resin for use in DLP, LED, SLA, or MSLA printers at 405 nm wavelength. This resin is the first commercial Kynar® PVDF 3D printable resin. Light Link™ combines the high resolution of SLA 3D printing with the material properties of PVDF to produce parts that rival the quality of injection molding products.

Applications

-

Detailed prototypes with exact dimensional tolerances

-

Low-volume high-quality prints

- Invisible layer lines

Light Link™ SLA resin for 3D printing is designed for printing Kynar® PVDF parts using low-cost consumer-grade SLA printers. Whether you want to print small PVDF parts with careful detail or large complex components, Light Link™ is up to the task. Our low-odor resin prints with ease and requires short exposure times and convenient post-processing methods. Light Link™ is formulated for low shrinkage and easy removal from the build plate. No matter the printing task at hand, Light Link™ delivers a quality result.

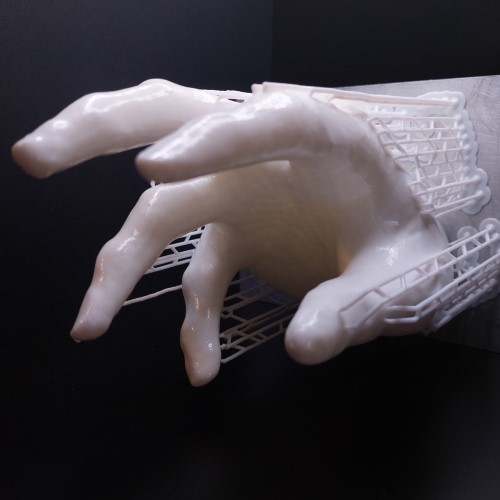

Light Link™ prints are a beautiful, glossy white color. These parts have scratch-resistant properties and almost invisible layer lines. Approaching the quality of injection molded parts Light Link™ prints are a cost-effective alternative without the mold expense. Easy print resin produces parts that clean up with standard post-processing procedures. Wash with IPA and post-cure with UV light, like all other 3D printed resins. There are no expensive printers, complex slicer settings, steep learning curves or extra accessories required to create beautiful Light Link™ parts.

Each bottle contains 1 kilogram of Light Link™ photopolymer resin. Always shake well before using and keep stored at 15-25 °C.

-

White Photopolymer Resin and Finished Parts

-

Invisible Layer Lines

-

High-Performance Prints

-

Excellent Tensile Strength

-

Moderate Impact Strength

-

Moderate Elongation

-

Scratch Resistant Prints

- Low Odor Resin

-

Compatible with Most Low-Cost SLA Printers

-

Shake the bottle vigorously for 60 – 120 seconds before use.

-

Allow the Light Link™ resin to rest for a few minutes after shaking to allow air bubbles to dissipate before adding to the vat.

-

Begin printing!

- The PVDF SLA Resin can be poured back into the bottle for reuse. Always use appropriate filtration methods when returning used PVDF SLA resin to the bottle to restrict cross-contamination and to exclude polymerized pieces of resin. For more information on handling the resin, see SDS and TDS.

-

Resin Vat Temperature: Heated vats are not required. Light Link™ resin prints using any vat. Print between 15 – 30 °C

-

Normal Layer Exposure Time: 5.0 – 9.5 seconds (7.0 seconds is generally recommended)

-

Bottom Layer Exposure Time: 30.0 – 55.0 seconds (45.0 seconds is generally recommended)

-

Post-Processing: Wash prints using 99% Isopropyl alcohol for 5 – 10 minutes. Let air dry. UV cure for 2-10 minutes (depending on the size of the print). For superior prints, wash prints with Isopropyl alcohol for 5 – 10 minutes and let air dry. Any post-processing techniques can be performed at this time.

-

Adhesion: To improve bottom layer adhesion, gently sand the build plate of the printer. Please consult with your specific SLA instruction manual before modifying the printer.

-

Container: Bottle

-

Net Weight: 1 kg

-

Wavelength: 385 – 405nm

-

FlashForge Hunter DLP Printer

-

Elegoo Saturn MSLA Printer

-

Elegoo Mars Series SLA Printers

-

Elegoo Series MSLA/SLA Printers

-

Phrozen Series MSLA/SLA/DLP printers

-

Anycubic Series MSLA/SLA/DLP Printers

Note: More printers will be added to the list as they are tested.