Electrostatic Dissipative PVDF Filament: Fluorinar-ESD™

Fluoropolymers such as PVDF have very high resistivity and are often used as an insulating water in wire and cable applications. The flow of electrons can be improved by the addition of a conductive material to the PVDF such as carbon black. However, a large amount of conductive material must be compounded with the PVDF in order to achieve electrical conductivity. This can result in a high melt flow viscosity creating a brittle material that is difficult to process by extrusion or injection molding

Electrical resistance in PVDF is greatly reduced without sacrificing mechanical properties by incorporating small amounts of graphene. This nano-compound provides static dissipation at ppm concentrations. The result is our PVDF filament with electrical static dissipative properties called Fluorinar-ESD™. Now you can print static dissipative parts while retaining the high-strength, impact and chemical resistance expected with Kynar® PVDF.

FLUORINAR-ESD™ PVDF PRINT SETTINGS

| Print Temp Range | 240 – 250 C |

| Bed Temp Range | 100 C |

| Cooling Fan | Optional |

| Print Speed Range | 10 – 30 mm/s |

| Bed Adhesion | Print objects on glass bed that is prepared with a thin layer of Elmer’s Disappearing Purple Glue Stick |

Additional information about Fluorinar-ESD™ PVDF filament and PVDF in general can be found on the following pages:

Fluorinar-ESD™ Safety Data Sheet (SDS)

Fluorinar™ Chemical Resistance Chart

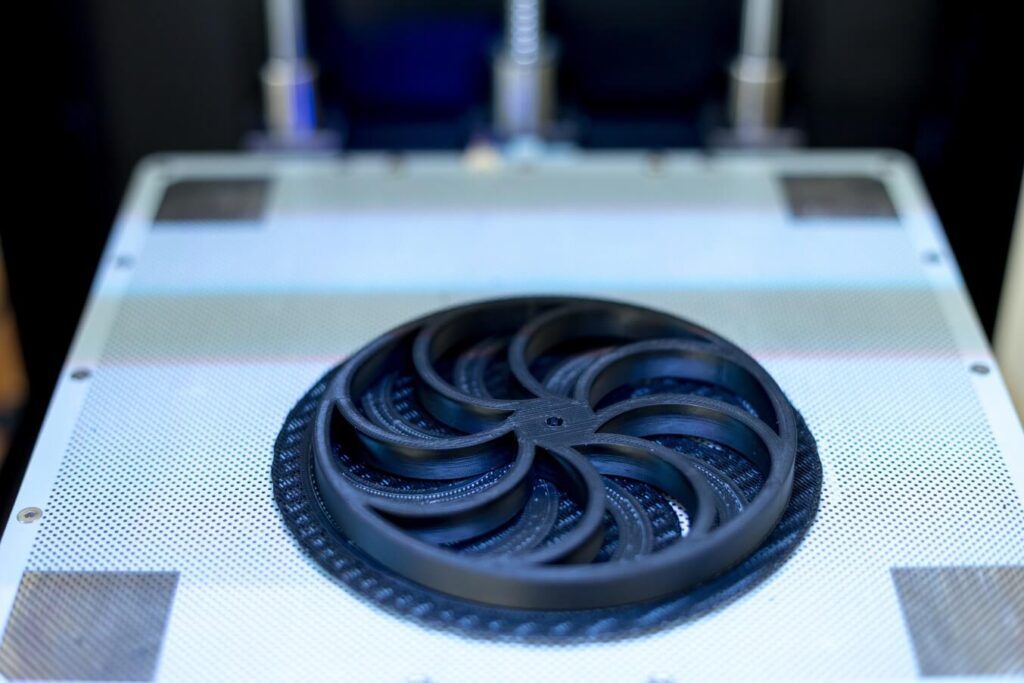

Successful Prints with Fluorinar™ PVDF Filaments

Reviews

There are no reviews yet.