Strong-Ty™ Cable Ties: sterile cable ties made with Kynar® PVDF

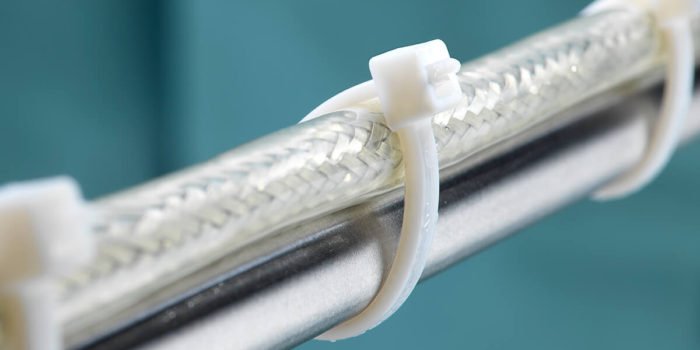

Strong-Ty™ PVDF cable ties can be sterilized by gamma radiation without any negative effects to material properties. The result is a cable tie ready for high purity applications in single-use pharmaceutical manufacturing or medical device equipment.

To determine the effects of gamma radiation, a series of cable ties were exposed to gamma radiation at a dosage range of 32.3 – 40.8 kGy. Testing was conducted by Sani-Tech West in conjunction with STERIS Isomedix Services. The cable ties were manufactured from polyethylene, nylon 6,6 and Kynar® PVDF. The effects of radiation exposure were compared by tensile elongation to unexposed cable ties. Mechanical testing was completed at the University of Utah Materials Characterization Lab. After exposure to sterilizing gamma radiation, Strong-Ty™ Kynar® PVDF cable ties performed as expected with no loss in strength or elongation. A copy of the test report is available here.

Strong-Ty™ cable ties are made in the USA by Nile Polymers using Kynar® PVDF. These cable ties are manufactured and packaged in a clean-room environment following an ISO 13485 procedure. In addition to their excellent chemical resistance, these cable ties exhibit minimal flame spread and smoke generation and meet the National Electrical Code NFPA-70A and UL94V-0 requirements for installation in building plenum. This material has also passed USP Class VI testing. Excellent material properties and attention to manufacturing and packaging details elevate Strong-Ty™ PVDF cable ties into a class by themselves.

Additional information about Strong-Ty™ Cable Ties and PVDF in general can be found on the following pages:

Strong-Ty™ Cable Tie TDS

Strong-Ty™ Cable Tie Engineering Drawing

Kynar® Chemical Resistance Chart

Accelerated Weathering of Kynar® PVDF – A Case For Better PV Cable Ties

Product Overview

Regulatory Compliance

Chemical Resistance

Sterilization

UV Resistance