Purisan™ PVDF Chemical Mixers: thick coated shaft with injection molded blades For many applications PVDF coatings provide a high purity surface while eliminating corrosion problems. However, a completely coated mixer is not the optimal material choice. Consider the leading edge of impeller blades. During daily use this surface comes in contact with the solution and

Author Archives: Howard Fisher

Purisan™ Kynar® mixers lead the way in custom mixing assemblies Before Purisan™ Kynar® mixers were available, ordering a high-purity or corrosion resistant mixer was painful process. First you called a mixer company, who manufactured the shaft and impeller. They delivered the completed to a coating company who prepared the surface and applied the coating. All

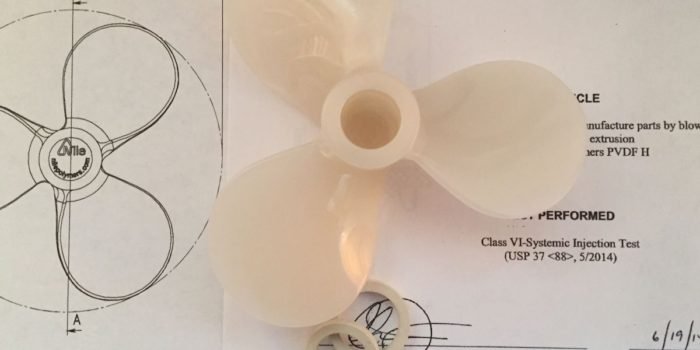

Single-Use Mixer: key component in pharmaceutical manufacturing Disposable bag technology is important in minimizing cost and contamination in biopharm production. When mixing is required, Purisan™ Kynar® PVDF single-use mixers can be incorporated directly into the bag prior to gamma sterilization. The Kynar® PVDF prop is injection molded and threads onto a Kynar® PVDF coated shaft.

ISO 10993 Testing The Nile Polymers Fluorostretch™ fluoroelastomer has passed ISO 10993 cytotoxicity testing. Patented by DuPont almost 60 years and sold under the Viton® tradename, the FKM fluoroelastomer is a PVDF and HFP Type I copolymer as defined in the ASTM D1418 standard. Fluorostretch™ fluoroelastomer plays an integral part in the Purisan™ PVDF mixers by

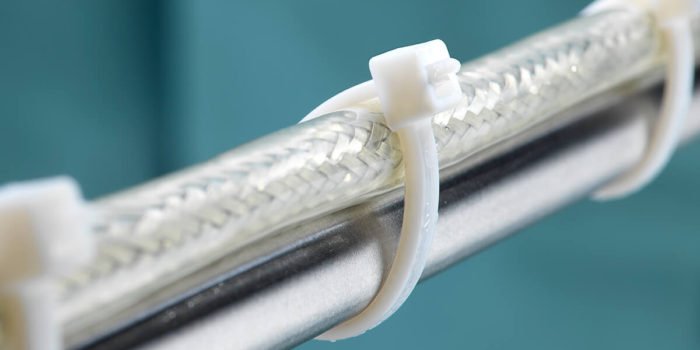

Strong-Ty™ PVDF Cable Ties: long-term UV resistance made possible by Kynar® Photovoltaic (PV) arrays have a 25-year plus life expectancy. However, the nylon and polyethylene cable ties can fail in a matter of months due to combinations of UV, temperature extremes, zinc chloride corrosion and high humidity. Commodity cable ties provide no dependable long-term solution

Strong-Ty™ Cable Ties: sterile cable ties made with Kynar® PVDF Strong-Ty™ PVDF cable ties can be sterilized by gamma radiation without any negative effects to material properties. The result is a cable tie ready for high purity applications in single-use pharmaceutical manufacturing or medical device equipment. To determine the effects of gamma radiation, a series of

Strong-Ty™ Cable Ties: superior performance with Kynar® PVDF The most common plastics used to manufacture cable ties are polyethylene, polypropylene, and nylon. These commodity plastics can come from thousands of sources including original manufacturers, compounders, and recyclers. Often the point of origin is price dependent and can change with each production run. While these cable

Strong-Ty™ Cable Ties: PVDF meets international regulations Concerns about material safety and traceability are more important than ever as cable ties made from inferior materials flood the market. In mission-critical applications polymer substitution or manufacturing shortcuts are unacceptable. How confident are you in your current cable tie? What materials, including additives, stabilizers, fillers, plasticizers and

Strong-Ty™: chemical resistant cable ties We choose to make our Strong-Ty™ cable ties from Kynar® PVDF and have never looked back. Kynar® PVDF offers a wider range of chemical resistance compared to other polymers. When your application involves aggressive chemical exposure at elevated temperatures, you need Strong-Ty™ chemical resistant cable ties. The following chart from

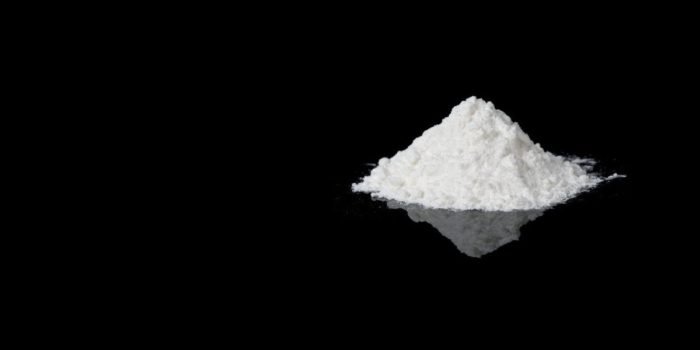

Kryptonar™ Powder: high purity PVDF coating system Kryptonar™ PVDF sets a new industry standard for extractable metal ions in a partially fluorinated polymer. Results from metal ion extraction testing at Balazs Labs using the Semi F57 procedure look very good. Your final products are only as good as your powder coating material so when you need

- 1

- 2