Nile Polymers and Tetra Growth Solutions are pleased to announce the formation of Intellectual Polymer Designs (IPD). The purpose of this joint venture is to design, manufacture and market photopolymer resins. Our first product is Light Link™ a UV crosslinked SLA resin made with Kynar® PVDF for 3D printing. Light Link™ produces injection-molded quality parts

Author Archives: Howard Fisher

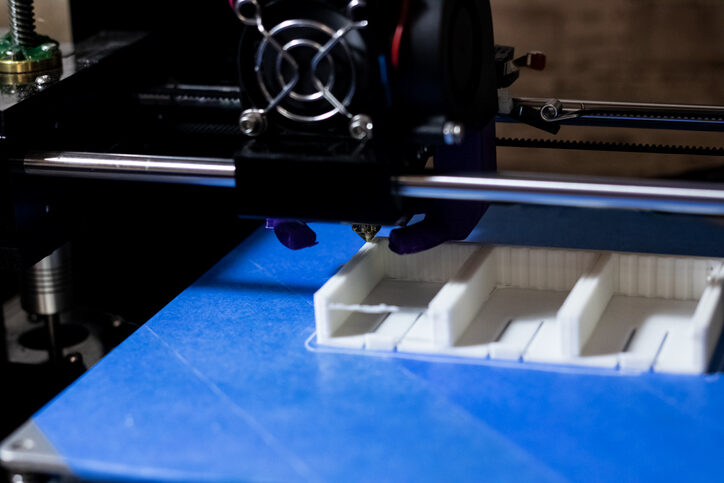

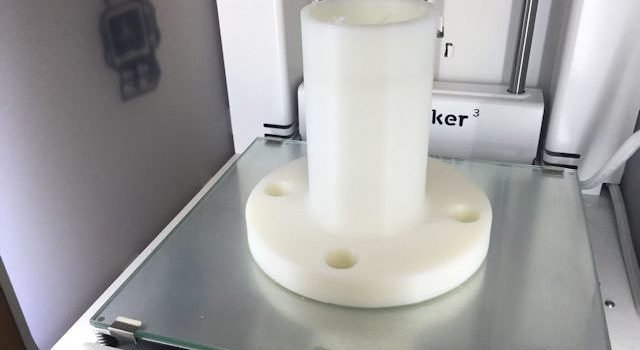

3D Prints for the Chemistry Lab with Kynar® PVDF In their report discussing 3D filament printing with PVDF, Tetra Growth Solutions makes a strong argument for the use of PVDF to print common lab components. Rising product costs, procurement difficulties, ease of printing and outstanding material properties support this case. Create your own corrosion-resistant parts

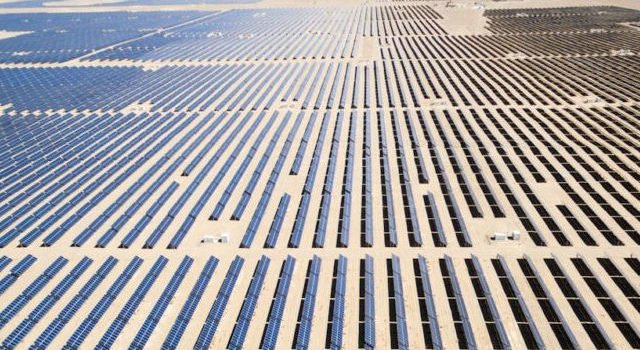

Strong-Ty™ Cable Ties: long-term UV resistance with Kynar® PVDF Nile Polymers, a leading manufacturer of high-performance cable ties, has expanded the range of industries they serve. Traditionally, cable ties made from Kynar® PVDF have shown durability across the solar and wire management industries. Known for their exceptional UV performance, smoke and flame resistance, and strong

Material Testing Achievements for Nile Polymers Products Nile Polymers is pleased to announce that our Fluorinar-C™ Kynar® PVDF filament along with our Strong-Ty™ Kynar® PVDF cable ties have passed the cytotoxicity testing standards for ISO 10993-5:2009. This important material qualification provides additonal confidence not available in other filament and cable tie products. The ISO page

The Fluorinar™ Kynar® PVDF Filament Family Expands Nile Polymers is pleased to announce the addition of two new filaments in the Fluorinar™ PVDF family: Fluorinar-B™ and Fluorinar-ESD™. Both materials are built on a foundation of Arkema’s Kynar® PVDF. Unlike other PVDF filaments, Fluorinar™ filaments contain no additional polymer additives or diluents. They provide the best

Unlimited Print Size: Fluorinar-C™ filament with Kynar® PVDF prints flat objects Nile Polymers is excited to announce our new Fluorinar-C™ filament made from Arkema’s Kynar Flex® PVDF copolymer. Available in both 1.75 and 2.85 mm diameters, our 3D printing filament is ideal for printing large parts that remain perfectly flat during the printing process and

Synergy: Stronger together than apart Nile Polymers is pleased to announce a joint partnership with 3Dogg.com to distribute Fluorinar™ Kynar® PVDF filaments. This relationship allows customers outside of North America quicker access to Fluorinar™ PVDF filaments. Available in both 1.75 mm and 2.85 mm diameters this is the first Kynar® PVDF filament available to the 3D

Amazing Results: Fluorinar-H™ 3D PVDF filament delivers quality prints Nile Polymers is pleased to announce our new Fluorinar-H™ filament made from Arkema’s Kynar® PVDF homopolymer. Available in 1.75 mm and 2.85 mm diameters in a natural color, our 3D printing filament is ideal for printing applications in chemical or high-temperature environments. Outstanding properties of our

REVIEW OF THE NILE POLYMERS EXHIBIT AT THE 2017 CHEM SHOW IN NEW YORK WE OFFER CORROSION-RESISTANT PRODUCTS MADE FROM KYNAR® PVDF FOR THE CHEMICAL PROCESS INDUSTRY PURISAN™ PVDF MIXERS Kynar® injection-molded impellers and Kynar® powder coated shafts. Impellers are available up to 6 inch diameter and shafts up to 1.25 inch diameter and 7

Strong-Ty™ Solar Cable Ties: unchanged after long-term UV exposure Wire and cable management on the photovoltaic backplane is critical for safety and electrical continuity. Why jeopardize an entire PV installation with cable ties made from substandard polymers such as nylon and polyethylene? Even behind photovoltaic panels, nylon and polyethylene cable ties fail in reflected UV

- 1

- 2